Taking care of slot cars and tracks is the foundation of keeping the sets in the best possible conditions. Sure, sometimes the issues that occur can be out of your control.

But that doesn’t mean you shouldn’t invest your best efforts in maintenance.

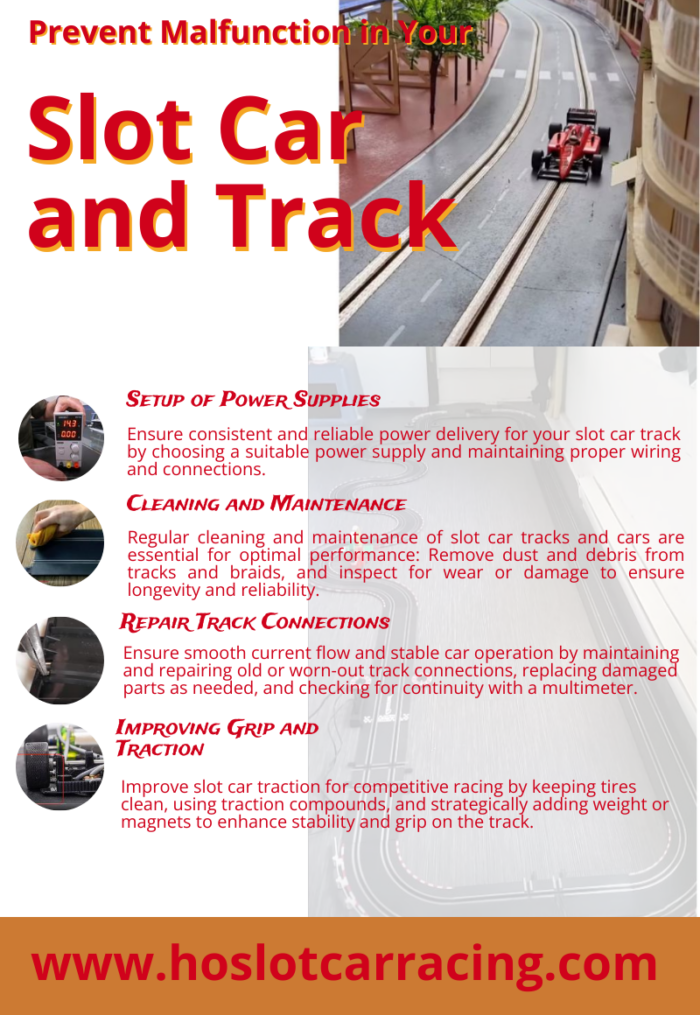

To help you with this aspect, I will share several maintenance tips you can use to prevent malfunction in your slot car and track. Buckle up, and let’s go.

Table of Contents

4. Proper Setup of Power Supplies

Setting up the correct power supply for your slot car track is fundamental to ensure consistent power delivery and prevent malfunctions.

A reliable power supply maintains steady voltage and current, crucial for smooth operation.

When building or choosing a power supply, consider the specifications of your slot cars and track. Not all are made equal, which means you need to conduct a bit of research.

Overpowering can damage the cars, while underpowering can result in sluggish performance.

It’s essential to use a power supply that matches the voltage requirements of your slot cars. Making a mistake in this regard can easily ruin the whole set, not just cars.

Adjustable power supplies are ideal as they allow you to fine-tune the voltage according to the car and track conditions.

Consistent power prevents issues like overheating and power surges, which can cause significant damage to the cars and track.

Proper wiring and connections are equally important. Secure all connections to avoid power loss and ensure a smooth flow of electricity.

Regularly check and replace any worn-out wires or connectors.

Using high-quality materials for wiring and connections will reduce resistance and provide a more reliable power delivery system.

Invest time in setting up a proper power supply, and you will ensure your slot cars perform at their best, offering a more competitive racing experience.

3. Regular Cleaning and Maintenance

Regular cleaning and maintenance of slot car tracks and cars are essential for maintaining good traction and electrical connectivity.

Dust and debris can accumulate on the track and the car’s braids, leading to reduced performance and increased wear.

Therefore, a cleaning routine is vital. For the tracks, use a soft cloth or sponge dampened with a mild cleaning solution to wipe away dust and grime.

Avoid using harsh chemicals as they can damage the track surface.

For stubborn dirt, a gentle scrubbing with a soft brush can help.

Ensure the track is completely dry before use to prevent electrical issues. The car’s braids, which are responsible for picking up power from the track, should also be cleaned regularly.

Use a small brush or a specialized braid cleaner to remove any accumulated dirt. If the braids are worn out, replace them to ensure optimal power transfer.

Preventative maintenance can significantly extend the life of your slot car equipment. Inspect the track for any signs of wear or damage and repair them promptly.

It includes checking for loose connections and securing them as needed.

2. Handling Track Connections and Old Tracks

Maintaining and repairing old or worn-out track connections are essential to ensure smooth current flow and stable car operation.

Over time, track connections can become loose or corroded, leading to inconsistent power delivery and performance issues.

To address these problems, start by inspecting all track connections regularly.

Look for signs of wear, such as rust or bent connectors.

Clean any corrosion using a mild abrasive or contact cleaner. For severely corroded connections, it may be necessary to replace the affected parts entirely.

If you encounter snapped blades or fins, they can often be repaired or replaced.

Use a small amount of epoxy or super glue to reattach broken pieces, ensuring a secure fit.

Replace the braids for track sections with worn braid connections to maintain a reliable power transfer. Reconnecting old track sections requires careful attention to ensure a tight fit.

Loose connections can lead to power drops and erratic car behavior. Use a multimeter to check for continuity across the connections, ensuring a smooth and uninterrupted current flow.

1. Enhancing Grip and Traction

Improving the grip and traction of slot cars on the track is crucial for competitive racing.

There are several methods to achieve this, starting with keeping the tires clean.

Regularly wipe the tires with a damp cloth to remove dust and debris. For deeper cleaning, use a mild soap solution to thoroughly dry the tires afterward.

Special products like braid conditioners can also enhance traction. Apply these products to the braids to improve electrical contact and reduce resistance.

Consider using traction compounds on the tires.

These compounds can increase the tire’s grip on the track, allowing for better handling and faster lap times.

Adding weight or magnets to the cars can further improve traction. Small weights can be strategically placed within the car’s chassis to lower the center of gravity, enhancing stability.

Magnets can be added to increase downforce, pressing the car more firmly onto the track.

Both methods can help prevent the car from sliding or spinning out during sharp turns.